The History of Fatigue Testing

The History of Fatigue Testing

Beginning in the first half of the 19th century, mechanical failures were observed to take place in metals and materials subject to repetitive stress well below their yield strength. The theory came to be that the metal became "tired" or "fatigued", hence the term "fatigue" or "metal fatigue".

In 1829 Wilhelm August Julius Albert, a German mining administrator, observed, studied, and reported on the failure of mine hoist cables resulting from repeated small loadings, this is first known recorded account of metal fatigue. He also developed a test machine for conveyor chains used in the mines.

Jean-Victor Poncelet, in his lectures at the military school at Metz in 1839 describes metals as being "tired".

In the early 1840s William John Macquorn Rankine examined many broken railway axles and discovered that the axles had failed due to the progressive growth of a brittle crack from a shoulder or stress concentration on the shaft. He presented his conclusions in a paper to the Institution of Civil Engineers.

In the early 1840s William John Macquorn Rankine examined many broken railway axles and discovered that the axles had failed due to the progressive growth of a brittle crack from a shoulder or stress concentration on the shaft. He presented his conclusions in a paper to the Institution of Civil Engineers.

In 1849, the British Government commissioned E. A. Hodgkinson to study the fatigue of wrought and cast iron used in railway bridges. In his report he described alternating bending experiments on beams with midpoints being repeatedly deflected by a rotating cam.

F. Braithwaite coins the term "fatigue" using it exclusively to denote the cracking of metals under repeated loadings in his report "On the fatigue and consequent fracture of metals". Institution of Civil Engineers, Minutes of Proceedings, 463-474. 1854.

Sir William Fairbairn a Scottish Engineer (1789 - 1874) was one of the first to conduct systematic investigations into the failures of structures such as bridges, mills, and boilers. At the request of the UK Parliament in 1861 he conducted research into metal fatigue by raising and lowering a 3 tonne mass onto a cylinder of wrought iron 3 million times before it fractured and showing that a static load of 12 tonne was needed to achieve the same result. Partially funded by the Board of Trade he built large scale testing set ups for his studies of the effects of repeated loading of wrought iron and cast iron girders, demonstrating that fracture could occur by crack growth from incipient defects, a problem now known as fatigue.

Sir William Fairbairn a Scottish Engineer (1789 - 1874) was one of the first to conduct systematic investigations into the failures of structures such as bridges, mills, and boilers. At the request of the UK Parliament in 1861 he conducted research into metal fatigue by raising and lowering a 3 tonne mass onto a cylinder of wrought iron 3 million times before it fractured and showing that a static load of 12 tonne was needed to achieve the same result. Partially funded by the Board of Trade he built large scale testing set ups for his studies of the effects of repeated loading of wrought iron and cast iron girders, demonstrating that fracture could occur by crack growth from incipient defects, a problem now known as fatigue.

August Wöhler (1819 - 1914) was a German engineer. He is remembered chiefly for his systematic work on metal fatigue. His work is the first to systematically characterize the fatigue behavior of materials using S-N Curves or Wöhler Curves. He developed a machine for repeated loading of railway axles, and showed clearly that fatigue failure occurs by crack growth from surface defects until the load can no longer be supported. In 1870 he summarizes his work on railroad axles, and concludes that cyclic stress range is more important than peak loads and introduces the concept of endurance limit. Wöhler was a member of the Technical Committee of the Verein Deutscher Eisenbahnverwaltungen, and favored the introduction of state-approved classifications for steel and iron. He also called for the founding of facilities for materials testing and testing equipment. He took part in teaching the theoretical and practical training of testing methods, but left the application and implementation of these to his assistant. With the construction of equipment for testing fatigue, Wöhler broke new ground in terms of methodology and testing technology, and had a significant impact on modes of thought in the technical disciplines.

August Wöhler (1819 - 1914) was a German engineer. He is remembered chiefly for his systematic work on metal fatigue. His work is the first to systematically characterize the fatigue behavior of materials using S-N Curves or Wöhler Curves. He developed a machine for repeated loading of railway axles, and showed clearly that fatigue failure occurs by crack growth from surface defects until the load can no longer be supported. In 1870 he summarizes his work on railroad axles, and concludes that cyclic stress range is more important than peak loads and introduces the concept of endurance limit. Wöhler was a member of the Technical Committee of the Verein Deutscher Eisenbahnverwaltungen, and favored the introduction of state-approved classifications for steel and iron. He also called for the founding of facilities for materials testing and testing equipment. He took part in teaching the theoretical and practical training of testing methods, but left the application and implementation of these to his assistant. With the construction of equipment for testing fatigue, Wöhler broke new ground in terms of methodology and testing technology, and had a significant impact on modes of thought in the technical disciplines.

Sir James Alfred Ewing KCB - Knight Commander of the Order of the Bath - (1855 - 1935) was a Scottish physicist and engineer. He was best known for his work on the magnetic properties of metals. He studied and named the phenomenon of hysteresis. He also studied the crystalline structure of metals, and in 1903 he was the first to propose that fatigue failures originated in microscopic defects or slip bands in material.

Sir James Alfred Ewing KCB - Knight Commander of the Order of the Bath - (1855 - 1935) was a Scottish physicist and engineer. He was best known for his work on the magnetic properties of metals. He studied and named the phenomenon of hysteresis. He also studied the crystalline structure of metals, and in 1903 he was the first to propose that fatigue failures originated in microscopic defects or slip bands in material.

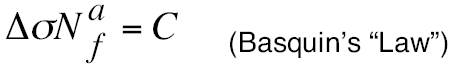

O. H Basquin in 1910 proposed empirical laws to characterize the S-N curves of metals. He showed that a log-log plot of the stress versus the number of fatigue cycle resulted in a linear relationship over a large range of stress. Basquin's Law is still used today.

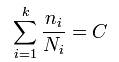

In 1945 M. A.. Miner popularizes A Palgrin's (1924) linear damage hypothesis as a practical design tool. It is now commonly referred to as Miner's rule. Miner's Rule states that where there are k different stress magnitudes in a spectrum, Si (1 ≤ i ≤ k), each contributing ni(Si) cycles, then if Ni(Si) is the number of cycles to failure of a constant stress reversal Si, failure occurs when:

C is experimentally found to be between 0.7 and 2.2. Usually for design purposes, C is assumed to be 1.

S. S. Manson and L. F. Coffin in 1954 Explain fatigue crack growth in the tip of the cracks. The Coffin-Manson relation describing low-cycle fatigue in terms of strain in the material, and is independently published by S. S Manson In 1953 and by L. F. Coffin in 1954.

![]()

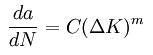

In the face of initial skepticism and popular defense of Miner's phenomenological approach P. C. Paris in 1961 proposes methods for predicting the rate of growth of individual fatigue cracks.

P. C. Paris, M. P. Gomez and W. E. Anderson (A rational analytic theory of fatigue, The Trend in Engineering, 1961) derive relationships for the stage II crack growth with cycles N, in terms of the cyclical component ΔK of the Stress Intensity Factor K.

Where "a" is the crack length and "m" is typically in the range 3 to 5 (for metals). This is often referred to as Paris' Relationship.

This relationship was later modified (Forman, R.G., Kearney, V.E. and Engle, R.M. (1967). Transactions of the American Society of Mechanical Engineers, Series D; Journal of Basic Engineering, 89(3): 459–465) to make better allowance for the mean stress, by introducing a factor depending on (1-R) where R = min. stress/max stress, in the denominator.

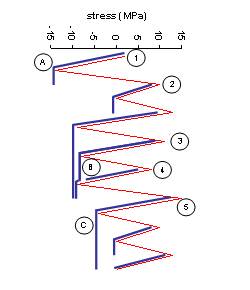

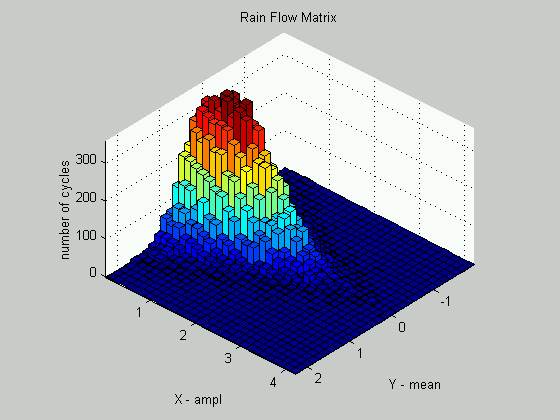

In 1968 Tatsuo Endo and M. Matsuiski devised a rainflow-counting algorithm and apply it to Miner's rule enabling its reliable use in cases involving random loads. The methodology has progressed to a very sophisticated level with various software packages available. ASTM E 1049 Section 5.4 (standard practices for cycle counting in fatigue analysis: Rainflow Counting and Related Methods) is often referenced as a standard for this method.

In 1968 Tatsuo Endo and M. Matsuiski devised a rainflow-counting algorithm and apply it to Miner's rule enabling its reliable use in cases involving random loads. The methodology has progressed to a very sophisticated level with various software packages available. ASTM E 1049 Section 5.4 (standard practices for cycle counting in fatigue analysis: Rainflow Counting and Related Methods) is often referenced as a standard for this method.

|

Wolf Elber in 1970 elucidates the mechanisms and importance of crack closure in slowing the growth of a fatigue crack due to the wedging effect of plastic deformation left behind the tip of the crack. |

Need Fatigue Testing? Fill out our secure online RFQ form and we’ll respond quickly.