ASTM E1508

Energy Dispersive Spectroscopy using an Electron Scanning Microscope SEM/EDS: ASTM E 1508

At Westmoreland Mechanical Testing & Research ASTM E 1508 is the most commonly employed specification for Scanning Electron Microscope / Energy Dispersive Spectroscopy.

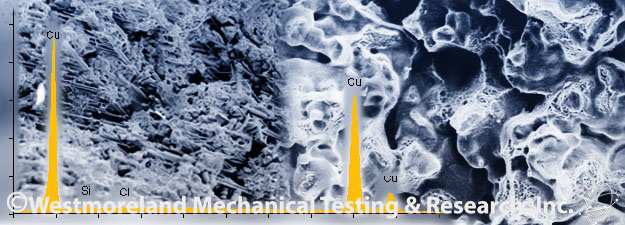

Energy Dispersive Spectroscopy or EDS is a method of quantifying the elemental constituents of a sample by measuring with an Electron Scanning Microscope the number of x-rays produced by a solid sample when irradiated by electrons versus the energy of those x-rays. Feature or phases as small as 1µm can be analyzed.

When the sample is bombarded by the electron beam of the Scanning Electron Microscope, electrons are ejected from the atoms comprising the sample's surface. A resulting electron vacancy is filled by an electron from a higher shell, emitting an x-ray to balance the energy difference between the two electrons.

The Energy Dispersive Spectroscopy's x-ray detector measures the number of emitted x-rays compared to their energy. The energy of the x-ray is characteristic of the element from which the x-ray was emitted. A spectrum of the energy versus relative counts of the detected x-rays is obtained and evaluated to determine quality and quantity of elements present in the sample.

Elements with atomic numbers from beryllium to uranium can be detected. Depending on the element and matrix, the minimum detection limits vary.

Quantitative results are readily obtained without standards. However, the accuracy of standard-less quantitative analysis is highly dependent on the sample. Greater accuracy is obtained using known standards with similar structure and composition as the unknown sample.

Line profile analysis:

The Scanning Electron Microscope's electron beam is scanned along a pre-determined line across the sample while x-rays are detected for specific positions along that line. Analysis of the x-ray energy spectrum at each position provides plots of the relative elemental concentration for each element compared to position along the line.

Elemental mapping:

Characteristic x-ray intensity is measured relative to lateral position on the sample surface. Variations in x-ray intensity then indicate the relative elemental concentrations across the surface. Maps are recorded using image brightness intensity as a direct function of the local concentration of the element or elements present. Lateral resolution of about 1µm is possible.

SEM/EDS is typically used for:

- Surface contamination analysis

- Corrosion evaluations

- Coating composition analysis

- Rapid material alloy identification

- Small component material analysis

- Phase identification and distribution